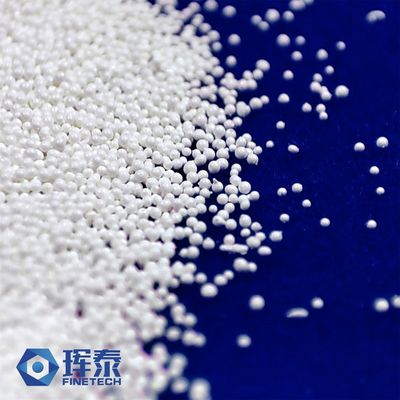

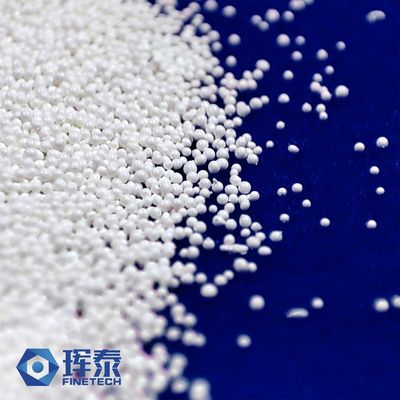

Deburring Ceramic Beads Blasting Media 850-1180μM For Optimal Surface Preparation

| Shape | Particle | Usage | Sandblasting |

|---|---|---|---|

| Name | Ceramic Cleaning Media | Usage | Deburring |

| Material | Ceramic | Size | 425-600μm |

| Highlight | Deburring Ceramic Blasting Media,Ceramic Beads Blasting Media 850um,65% Zro2 Ceramic Blasting Beads |

||

Product Description:

Ceramic Beads Blasting Media 850-1180μM For Optimal Surface Preparation

Applications:

1. Medical Treatment

In the medical field, surface treatment is an essential process for stainless steel surgical instruments and titanium alloy human implanted devices. This includes deburring, which is the removal of any rough edges or protrusions on the surface, to ensure the instruments are safe and smooth for use in surgeries. This process helps to improve the overall quality of these devices and ensure patient safety.

2. High Iron FieldThe use of ceramic shot is also prevalent in the high iron field, where it is used for sandblasting the surface of aluminum alloy parts to achieve a smooth satin effect. This process helps to enhance the metal texture and improve the appearance of high-speed rail components. Additionally, ceramic shot is used for grinding and finishing in this industry.

3. Automotive FieldIn the automotive industry, ceramic shot is used for a variety of purposes. It is commonly used for surface cleaning and deburring of engine castings, as well as for cleaning welds and spot welding on car floors in preparation for subsequent spraying. It is also used for shot peening of automobile springs, which helps to improve their fatigue life. Furthermore, ceramic shot is used for sandblasting aluminum alloy automobile wheels, eliminating stress and improving impact resistance.

4. Mold and MachiningIn the mold and machining industry, ceramic shot is used for sandblasting stainless steel molds, copper molds, and aluminum alloy molds. This includes molds for tires, injection molding, and stamping. The process helps to improve the surface finish of these molds by removing any burrs or flash. It is also used for cleaning and finishing machined parts.

Customization:

- Brand Name: Fine-Tech

- Product Name: Ceramic Bead Blasting

- Model Number: B30

- Place of Origin: Changsha, China

- Minimum Order Quantity: 500kg

- Price: Negotiation

- Packaging Details: 25kg/barral, 25kg/bag, 1t/pallet

- Delivery Time: 5-15 work days

- Payment Terms: L/C, T/T

- Supply Ability: 2000t per year

- Color: White

- Usage: Sandblasting

- Zro2: 65%

- Cost: Moderate

Packing and Shipping:

When purchasing our Ceramic Bead Blasting product, you can expect the following packaging and shipping options:

- Individual packaging in plastic bags for easy handling and storage

- Bulk packaging in sturdy cardboard boxes for larger orders

- Customized packaging options available upon request

- Standard shipping via ground transportation for domestic orders

- Expedited shipping options available for urgent orders

- International shipping available for global orders

Rest assured that our Ceramic Bead Blasting product will be carefully packaged and shipped to ensure safe delivery to your desired location. If you have any specific packaging or shipping requests, please feel free to contact us and we will do our best to accommodate your needs.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Fine-Tech. - Q: What is the model number of this product?

A: The model number of this product is B30. - Q: Where is this product made?

A: This product is made in Changsha, China. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 500kg. - Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable. - Q: What are the packaging details for this product?

A: The packaging details for this product are 25kg/barral, 25kg/bag, and 1t/pallet. - Q: How long does it take for this product to be delivered?

A: The delivery time for this product is 5-15 work days. - Q: What are the payment terms for this product?

A: The payment terms for this product are L/C and T/T. - Q: What is the supply ability for this product?

A: The supply ability for this product is 2000t per year.