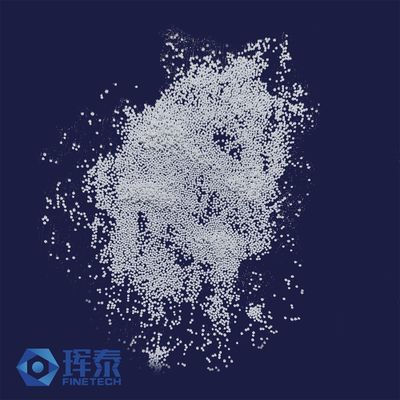

Ceramic Bead Blasting For Consistent And Thorough Surface Finishing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Finish | Smooth | Material | Ceramic |

|---|---|---|---|

| Name | Ceramic Cleaning Media | Application | Abrasive Refractory Industry |

| Zro2 | 65% | Usage | Sandblasting |

| Highlight | Abrasive Ceramic Bead Blasting,Surface Finishing Ceramic Bead Blasting,Sandblasting Ceramic Abrasive Media |

||

Product Description:

Zirconia is the key component used in ceramic shot, primarily for surface treatment processes such as sand blasting and shot peening. The production of ceramic shot involves melting high-quality imported zircon sand at high temperatures to create a liquid substance, which is then sprayed into spherical forms. These zirconia ceramic spheres are then separated and filtered using magnetic techniques to obtain round particles with high strength and uniform sizes.

The spherical particles of ceramic shot are exceptionally effective in achieving a polished finish during sandblasting, without altering the color of the workpiece. As a result, it is widely used in various industries for sandblasting and surface treatment, including aviation parts, stainless steel plates, structural components, stainless steel kitchenware, medical devices, as well as the manufacturing of mobile phone and laptop shells, vehicle chassis and engines, and sports equipment.

Applications:

Medical treatment often involves surface treatment techniques, such as deburring, of stainless steel surgical instruments and human implanted devices made from titanium alloy. These techniques help to improve the overall quality and functionality of these medical instruments and devices.

A technique known as high iron field is commonly used in the sandblasting process for aluminum alloy parts. This process helps to enhance the metal texture and creates a smooth satin finish. It is commonly used for high-speed rail grinding and finishing processes.

Ceramic shot is a commonly used material for surface cleaning and deburring of automotive engine castings. It is also used for cleaning welds and welding spots on car floors to prepare for subsequent spraying. In addition, it is used for shot peening of automotive springs to improve their fatigue life. Another common use is for beautification and sandblasting of aluminum alloy wheels, which helps to eliminate stress and improve impact resistance.

Ceramic shot is also used in the mold and machining industry for sandblasting stainless steel, copper, and aluminum alloy molds. By using this technique, surface finish can be improved, and flash and burrs from machined parts can be removed.

Customization:

Brand Name: Fine-Tech

Model Number: B60

Place of Origin: Changsha China

Minimum Order Quantity: 500kg

Price: Negotiation

Packaging Details: 25kg/barral, 25kg/bag, 1t/pallet

Delivery Time: 5-15 work days

Payment Terms: L/C, T/T

Supply Ability: 2000t per year

Name: Ceramic Cleaning Media

Cost: Moderate

Usage: Sandblasting

Size: 850-1180μm

Process: Bead Blasting

Keywords: Ceramic Bead Blasting, ceramic beads blasting media, zirblast ceramic beads, fine-tech, B10, customized service, Changsha China, minimum order quantity, negotiation, packaging details, delivery time, payment terms, supply ability, ceramic cleaning media, moderate cost, sandblasting, 850-1180μm size, bead blasting

Packing and Shipping:

Each unit of Ceramic Bead Blasting is carefully packaged to ensure safe delivery to our customers. The packaging includes:

- Individual plastic bags for each ceramic bead

- Sturdy cardboard box with foam inserts

- Protective bubble wrap to prevent any damage during transit

- Clear labeling for easy identification

We offer a variety of shipping options to meet the needs of our customers. These include:

- Standard ground shipping

- Expedited shipping for urgent orders

- International shipping to select countries

Our team takes great care in preparing each order for shipping and we strive to deliver your Ceramic Bead Blasting as quickly and safely as possible.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Fine-Tech. - Q: What is the model number of this product?

A: The model number of this product is B60. - Q: Where is this product manufactured?

A: This product is manufactured in Changsha, China. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 500kg. - Q: Is the price negotiable for this product?

A: Yes, the price is negotiable. - Q: What are the packaging details for this product?

A: The packaging details for this product are 25kg/barral, 25kg/bag, and 1t/pallet. - Q: How long will it take to receive the product?

A: The delivery time for this product is 5-15 work days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are L/C and T/T. - Q: What is the supply ability for this product?

A: The supply ability for this product is 2000t per year.