Ceramic Bead Blasting for Improved Productivity in Refractory Industry

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Ceramic | Shape | Customizable |

|---|---|---|---|

| Usage | Deburring | Process | Bead Blasting |

| Shape | Particle | Name | Ceramic Cleaning Media |

| Highlight | Ceramic Bead Blasting,Improved Productivity Ceramic Bead Blasting,Refractory Ceramic Bead Blasting |

||

Product Description:

Z series Ceramic beads shot peening media are zirconia-based ideal shot peening beads with high hardness and high strength, and widely used in aerospace industry and automotive industry.

B series Ceramic beads blasting media are zirconia-based blasting beads with high hardness and surface smoothness. As one recyclable sandblasting media, it is suitable for the blasting, finishing, cleaning, deburring, surface pretreatment in the process of metal parts production and maintenance.

This ceramic sand product is made by using unique technological formula, special production technology and high temperature fixed phase synthesis method above 2000℃. The ceramic sand can generate a gentle grinding effect, resulting in a uniform surface profile and matte finish, which is durable and efficient without inlaying contamination to the metal body. Low dust content, high degree of sphericity, smooth spherical and high toughness ensure excellent performance of ceramic sand products. They are suitable for sandblasting the surfaces of various steel, aluminum and other non-ferrous metal alloys to remove oxides, rust, sand, coatings and burrs. It can clean molds, engine parts, turbomachinery parts, welded steel parts, forged and cast metals and other various industrial components. Providing high quality components with outstanding aesthetic appearance in a variety of applications such as automotive, aerospace, electronics, home appliances, sporting goods and construction to achieve outstanding smooth and even surface finish on the parts being treated.

Features:

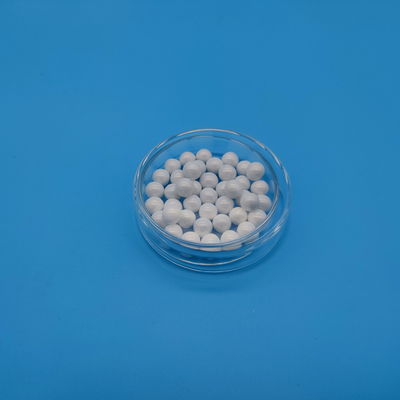

White color, high sphericity and smooth surface beads.

Because of the spherical and smooth surface of ceramic sand, it does not damage the workpiece. Its good elasticity enables it to bounce back from multiple angles during sandblasting, which makes it suitable for metal and complex plastic structures. Furthermore, it can also eliminate stress and extend the service life of the workpiece.

Utilization rate(20 – 30 times) higher than glass blasting media.

Ceramic sand has a low breakage rate, effectively reducing the number of times of reloading not only the supplies, but also that of labor, thus reducing the cost of usage cost-effectively. Additionally, the surface finish of ceramic sand is higher, and its service life is improved by about 20-30 times in comparison to that of glass sand. It also has a lower dust content, which is good for the environment and causes no potential silicosis.

High hardness, unbreakable, can be recycled and used repeatedly, long service life, reduce energy consumption and reduce costs.

The size distribution of ceramic sand is uniform, with no porosity, high toughmess, hardness and impact resistance. It has a higher particle density than glass bead, and its elastic modulus is 330GPa, much higher than the 60GPa derived from glass beads, allowing for a higher impact energy. Through reducing the shot peening pressure, it is able to achieve the same technological effect, yet with higher efficiency and lower energy consumption. The ceramic sand also has good stability, and is resistant towards to corrosion, high temperatures and small coefficient of thermal expansion as well as high insulation.

Lower metal surface roughness.

The density of ceramic sand is located between glass sand and steel sand, while its hardness is larger than most. In the sandblasting range, it covers the lower and upper blind spots of strength range of glass sand and steel sand. Additionally, there is no element contamination to the workpiece, while there is no metal powder residue on the workpiece surface, and no color distortion, which would otherwise reduce the natural color of the metal.

Lower wear rate

Due to its smmoth surface and rounded solid shape, ceramic sand can be rebound from multiple angles, and in turn result in lower wear rate when used in sandblasting process. Additionally, it contains 62-66% of ZrO2, leading to a higher level of toughness and hardness.

Less operation pressure and reduced abrasive velocity needed than glass blasting media, thus have far less abrasive breakdown and dust generation, results in cleaner working environment and better operator visibility.

Ceramic beads requires less operation pressure and velocity than glass blasting media, significantly reducing abrasive break-apart and dust creation. This leads to a cleaner working enviroment and better visibility for the operator.

Technical Parameters:

|

|---|

Applications:

Sandblasting with ceramic beads can be used as a thorough, universal, and extensive method for surface cleaning and pretreatment before coating or plating. It is more efficient, thorough and cheaper than other pretreatment processes and allow you to freely choose the cleanliness and roughness of your workpiece. This process generates compressive stress on the surface of the substrate, removes the surface oxide film, and causes lattice distortion of part of the surface metal, which in turn facilitates the physical and mechanical bonding of the coating.

Additionally, ceramic shot is widely used in many different areas, including medical treatment, high iron field, automotive industry, mold and machining, and electronic equipment.

The quality of the pre-treatment of the sandblasting process is highly important as it affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. Unattended rust can spread under the coating causing the coating to fall off in pieces.

Customization:

Fine-Tech's Ceramic Bead Blasting Service is the perfect choice for all your deburring needs. Our ceramic bead abrasive blasting utilizes ceramic beads for a smooth finish on a variety of materials. The Brand Name is Fine-Tech, the Model Number is B10, and the Place of Origin is Changsha China. The minimum order quantity is 500kg and the price is negotiable. The packaging details are 25kg/barral, 25kg/bag, and 1t/pallet. The delivery time is 5-15 work days and the payment terms are L/C, T/T. We have a Supply Ability of 2000t per year and the cost is moderate. The material is ceramic and the finish is smooth. The name is Ceramic Cleaning Media and the usage is deburring.

Support and Services:

Ceramic bead blasting is an efficient and cost effective way to clean and prepare surfaces for further treatment, such as painting, coating, or other finishing processes. We offer comprehensive technical support and services for ceramic bead blasting to help you get the most out of your equipment.

Our team of experienced technicians can provide you with the technical support and advice you need to ensure your ceramic bead blasting equipment is operating safely and effectively.

- Troubleshooting and diagnostics

- Equipment maintenance and repair

- Process optimization and advice

- Safety and environmental advice

We offer a range of services to keep your ceramic bead blasting equipment in optimum condition and ensure it is always ready to go.

- Equipment installation and setup

- Equipment upgrades and modifications

- Replacement parts and consumables

- Regular maintenance and servicing

Packing and Shipping:

Ceramic Bead Blasting packaging and shipping:

Packaging: Ceramic Bead Blasting products will be securely packaged in bubble wrap, cardboard boxes, and/or other protective packaging materials.

Shipping: Ceramic Bead Blasting products will be shipped via UPS, FedEx, or other reliable carriers. Delivery time may vary depending on the destination.