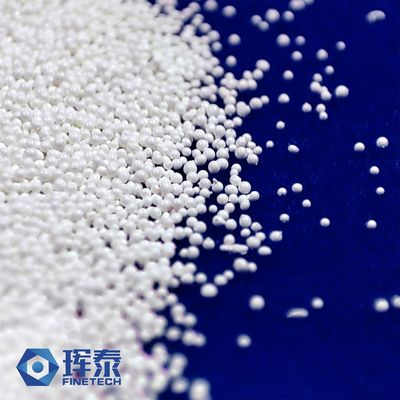

Industrial Ceramic Bead Blasting Process for Quality Results

| Zro2 | 65% | Material | Ceramic |

|---|---|---|---|

| Process | Bead Blasting | Size | 125-250μm |

| Shape | Customizable | Color | White |

| Highlight | Industrial Ceramic Bead Blasting,65% Zro2 Ceramic Bead Blasting,Customizable Ceramic Polishing Beads |

||

Product Description:

Ceramic bead blasting is the process of using ceramic bead abrasive media to gently clean and refine surfaces. Our ceramic bead cleaning media is made from high quality ceramic material, and is available in various shapes and sizes to meet your needs. The ceramic bead media is white in color and can be customized to fit the desired shape. It is suitable for a variety of surface cleaning and polishing applications, and can be used to remove contaminants from the surface while preserving the integrity of the surface. Ceramic bead blasting is an effective and efficient way to clean and refine surfaces, and provides a high level of accuracy and control.

Our ceramic bead abrasive is designed for use in a variety of blasting and cleaning applications. It is extremely durable and resistant to wear, making it an ideal choice for a wide range of applications. The ceramic beads are designed to provide a high level of accuracy and control, and can be used to achieve the desired finish on a variety of surfaces. The ceramic beads are also designed to be easy to use, and require minimal maintenance and upkeep.

Ceramic Beads blasting media are high-tech blastingmedia which are made by high quality zirconia powder as raw material, then fused in an electric furnace under high temperature over 2000 degrees, finally made into different micro beads through special technology.

Features:

Lower wear rate

Ceramic beads has smooth surface and round solid shape,it can be rebunded in multi-angles,so it has lower

wear rate in blasting process

High hardness and toughness

Ceramic beads contains 62-66% ZrO2,it has higher hardness over 700HV and fracture toughness,which willplay an important role in blasting process.

Applications:

1. Mold and machining: used for sand blasting of stainless steel mold, copper mold and aluminum alloy mold, such as tire mold, injection mold and stamping mold, to improve surface finish. Clean the flash and burr of machined parts.

2. Electronic equipment field: ceramic shot is used for sandblasting the shells of mobile phones, tablet computers and watches made of aluminum alloy or stainless steel. It can adjust the roughness and gloss of the surface as required, and has the characteristics of anti fingerprint.

3. Kitchen utensils industry: it is used for sandblasting of high-quality stainless steel cookware, pot bottom, soup spoon and other products, giving the products delicate metal texture and certain antibacterial ability.

4. Glass products industry: used for atomization treatment of glass, replacing hydrofluoric acid chemical etching process to prevent pollution.

Support and Services:

We provide professional technical support and service for our Ceramic Bead Blasting products. Our team of experienced engineers and technicians is available to answer any questions you may have about the installation, operation or maintenance of our products. We also offer on-site technical support and training to ensure that your equipment is used correctly and safely.

FAQ:

A1: Ceramic Bead Blasting is a process that uses fine ceramic beads as abrasive material to blast and clean surfaces of metal, plastic and other materials. It is a safe and effective method for removing rust, oxide, paint and other contaminants from surfaces.

A2: The Brand Name is Fine-Tech and the Model Number is B60.

A3: Ceramic Bead Blasting is produced in Changsha, China.

A4: The minimum order quantity for Ceramic Bead Blasting is 500kg.

A5: The price of Ceramic Bead Blasting is negotiable. The packaging details are 25kg/barral, 25kg/bag, 1t/pallet. The delivery time is 5-15 work days and the payment terms are L/C, T/T. The supply ability is 2000t per year.