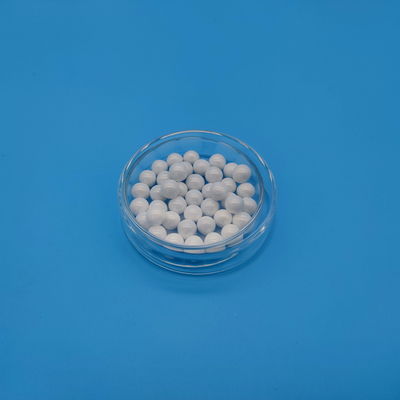

White Ceramic Beads Blasting Media Smooth Finished

| Finish | Smooth | Zro2 | 65% |

|---|---|---|---|

| Name | Ceramic Cleaning Media | Size | 425-600μm |

| Cost | Moderate | Shape | Customizable |

| Highlight | White Ceramic Beads Blasting Media,Smooth Ceramic Beads Blasting Media,Zro2 Ceramic Bead Blasting |

||

Product Description:

White Ceramic Beads Blasting Media - Moderate Cost Quality

The chief constituent of ceramic beads is zirconia, which is mainly used for surface treatments such as sand blasting and shot peening.

The production of ceramic shot uses high-quality imported zircon sand that is melted and then sprayed into small balls. These zirconia ceramic spheres are then sieved and separated via magnetic force to achieve higher roundness, strength, and uniform particle size.

When used for sandblasting, the spherical particles of ceramic shot create a brighter surface finish on the piece, all while not changing its color. This makes it useful in a wide variety of applications including, but not limited to, aviation parts, stainless steel plates, structural parts, stainless steel kitchenware, medical devices, and mobile phone and laptop shells. It is also used for automobile chassis/engines, and sports equipment.

Features:

Ceramic shot has many advantages due to its main component, zirconia, which is characterized by small crystal size and high wear resistance. For example, it has a high hardness of 700HV Vickers hardness (micro hardness) and 600HRC Rockwell hardness. It has a much higher density and specific gravity than glass beads. In addition, ceramic shot has the advantage of not producing dust since, due to its high strength and abrasion resistance, it is difficult to be broken during sandblasting.

Moreover, the sandblasting effect of ceramic shot is also very good. The surface is very smooth and the brightness is improved, especially compared to glass bead sandblasting. In addition, it can be used on various metals and nonmetals, and it will not react with metal or oxide, nor produce residue, so it will not affect the colour of the workpiece. Moreover, ceramic shot can be used in both dry and wet blasting and the service life is quite long, with a recycling time of 25 times of that of glass beads.

Lastly, ceramic shot also has a high roundness and the proportion of abnormal balls and snowman balls adhered between the spheres is low.

Applications:

In aerospace, shot peening is used to strengthen parts to withstand greater stresses. This process can also reduce the weight of the part, making aircraft lighter without sacrificing strength. In the automotive industry, shot peening can be used to extend the fatigue life of parts such as gearbox gears and automotive aluminum hubs. Stress-relieving, peen-forming, and peen-straightening are also possible.

Practical applications of shot peening also extend to the nuclear and chemical equipment industries. In the medical industry, shot peening is used for sandblasting satin finish, cleaning, deburring, and descaling. Additionally, it provides the necessary pretreatment for metal surfaces prior to spraying or coating.

Customization:

- Brand Name: Fine-Tech

- Model Number: B30

- Place of Origin: Changsha China

- Minimum Order Quantity: 500kg

- Price: Negotiation

- Packaging Details: 25kg/barral, 25kg/bag, 1t/pallet

- Delivery Time: 5-15 work days

- Payment Terms: L/C, T/T

- Supply Ability: 2000t per year

- Application: Abrasive Refractory Industry

- Usage: Sandblasting

- Material: Ceramic

- Shape: Customizable

- Process: Bead Blasting

Fine-Tech's Ceramic Bead Blasting is designed to meet different needs of customers. Our ceramic beads blasting media are made of high-grade ceramic that can be used in abrasive and refractory industries. We provide customized services to meet your specific requirements. Our ceramic beads are available in a variety of shapes and sizes, and can be tailored to meet your needs.

We guarantee quick delivery of your order within 5-15 working days and accept payment through L/C or T/T. Our supply capacity is up to 2000t per year. We offer the most competitive price and look forward to doing business with you.

Support and Services:

At ABC Company, we are dedicated to providing our customers with the best possible technical support and services for our Ceramic Bead Blasting products. Our experienced engineers are available to answer any questions you may have about our product and help you find the right solution for your needs.

We offer personalized support for each customer, and our team is committed to providing reliable assistance with installation, setup, and troubleshooting. We also provide comprehensive documentation and training materials to help ensure your product is being used safely and efficiently.

Our support team is available 24 hours a day, seven days a week. We are always happy to assist you with any technical issues, and our friendly staff is available to answer any questions you may have. Contact us today to learn more about our Ceramic Bead Blasting products and how we can help you get the most out of them!

Packing and Shipping:

Ceramic Bead Blasting Packaging and Shipping

Ceramic bead blasting is typically packaged in sealed plastic containers or bags. To ensure the product is protected during transit, we recommend shipping the product in sturdy cardboard boxes with protective packaging such as bubble wrap and/or foam. We also recommend using a shipping carrier that provides tracking information.