Hexagonal Brown Aluminum Oxide The Perfect Choice For Abrasive Cutting And Grinding

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Soluble In | Acids | Crystal Structure | Hexagonal |

|---|---|---|---|

| Industry | Diamond Tools | Composition | Alpha Alumina |

| Abbreviation | BFA | Shelf Life | 2 Years |

| Highlight | Brown Aluminum Oxide For Abrasive Grinding,Brown Aluminum Oxide For Abrasive Cutting,Hexagonal Brown Aluminum Oxide |

||

Product Description:

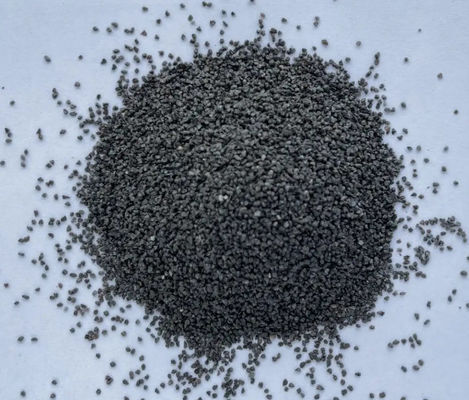

Brown Fused Alumina is created by fusing bauxite in an electric arc furnace at high temperatures. The resulting product has a brownish color and is incredibly hard and tough. The process of creating brown fused alumina involves using a tilting electric arc furnace. The resulting product has high temperature resistance, strong erosion resistance, high machinery strength, and thermal stability. It is an ideal material for manufacturing shaped refractories.

Brown Aluminum Oxide is made by fusing premium raw materials in a 3500 KVA furnace. It is the perfect material for use in general abrasive applications such as bonded abrasive tools, polishing, and sandblasting grit. Though it may have lower hardness and abrasive capacity than diamond, boron carbide, and silicon carbide, it is used widely for grinding ferrous materials and finishing tough, hard materials. It can also be used as high-class refractory materials. Brown Aluminum Oxide is available in macro and micro powder form, and comes in both F and P grades.

Features:

Brown corundum is an abrasive material that is commonly used for sandblasting surface treatment. Compared to other abrasive materials such as slag and quartz sand, brown corundum offers several advantages that make it ideal for this application.

The high density of brown corundum results in less dust during the sandblasting process. This is beneficial for operator health and safety, as well as improving visibility. Slag and quartz sand, on the other hand, produce smaller particles due to their brittleness and lower density, resulting in more environmental pollution.

Under pressure, brown corundum can quickly impact the surface of an object with a large number of sharp edges, making it a very fast spray grinding method. Its unique particle size ensures that more effective particles hit the surface of the object, resulting in a high cleaning rate that is twice as fast as other conventional abrasives.

The use of brown corundum can greatly reduce the loss of abrasive due to its unique particle size, allowing for more effective particles to hit the surface of the object.

Technical Parameters:

| Chemical | Percentage |

|---|---|

| Al2O3 | ≥96.3% |

| SiO2 | ≤1.4% |

| Fe2O3 | ≤0.21% |

| TiO2 | ≤1.5% |

- Color: brown

- Mohs hardness: 9

- True density: 3.9 g/cm3

- Bulk density: 1.60~1.95g/cm3

- Ig-Loss: ≤0.09%

Applications:

Sandblasting is widely used in various fields such as environmental protection materials, aluminum profile, copper profile, glass, washed jeans, and precision molds. It is a process of smoothing and cleaning a surface using abrasive materials propelled at high speed by compressed air or steam.

Grinding is another important process in many industries, especially in the manufacturing of electronic components and optical instruments. It is applied to picture tubes, optical glass, monocrystalline silicon, lenses, watch glass, crystal glass, jade, and other materials to achieve smoothness and precision.

Coating abrasives are used as raw materials for manufacturers of sandpaper and gauze. They are made of various abrasive materials coated onto a paper or cloth backing and are widely used in the automotive, woodworking, and metalworking industries.

Support and Services:

Brown Aluminum Oxide is a high-quality abrasive that is used for surface preparation, finishing, and polishing. It is typically used in blasting applications, grinding wheels, and sanding belts. It is a durable and long-lasting abrasive that provides consistent performance and a high-quality finish.

Our technical support team is available to assist you with any questions or concerns you may have regarding the use of Brown Aluminum Oxide. We can provide guidance on the proper usage of the abrasive and offer recommendations on the best application for your specific needs.

In addition to technical support, we also offer a range of services to our customers. These include custom packaging and labeling, product testing, and special formulations. Our goal is to provide you with the highest level of service and support to ensure your complete satisfaction with our product.

Packing and Shipping:

Product Packaging:

The Brown Aluminum Oxide product will be packaged in 25kg bags made of durable and high-quality materials to ensure the safety and integrity of the product during transportation and storage.

Product Shipping:

We will ship the Brown Aluminum Oxide product within 2-3 business days after receiving your order. We use reliable and trusted carriers to ensure that the product reaches you in perfect condition and on time. Shipping costs will be calculated based on the destination and weight of the product.