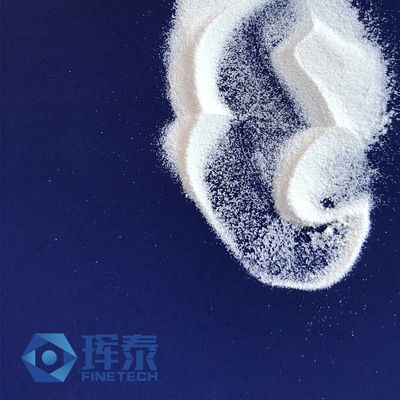

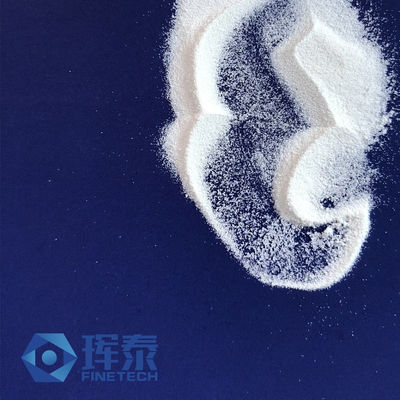

Particle Specific Ceramic Bead Blasting for Customizable Surface Preparation

| Name | Ceramic Cleaning Media | Color | White |

|---|---|---|---|

| Size | 850-1180μm | Finish | Smooth |

| Application | Abrasive Refractory Industry | Usage | Deburring |

| Highlight | Ceramic Bead Blasting Particle,Customizable White Ceramic Bead,Deburring White Ceramic Bead |

||

Product Description &

Features:

When it comes to achieving a consistent and high-quality surface treatment for metals, ceramic shot is the best choice. This metallic light has blasting strength that surpasses steel balls and glass beads. Its unique composition, specifically zirconia, allows for a deeper and more controlled metal depth.

Ceramic shot not only provides exceptional surface treatment, but it also has benefits for the environment. With a low crushing rate and absence of dust, it poses no harm to the human body. Its uniform particle size, high wear resistance, and re-elasticity make it a safe alternative to other blasting materials. Eliminating the risk of silicosis, ceramic shot is a responsible and eco-friendly choice.

One of the many advantages of using ceramic shot is its ability to protect blasting equipment. Its smooth surface, high sphericity, and low wear prevent damage to equipment during both dry and wet blasting processes. This makes it a highly efficient and cost-effective option, without sacrificing equipment quality.

- High strength and wear resistance due to zirconia composition

- High hardness with minimal risk of breakage

- No dust generated during sandblasting

- Provides a smooth and high-quality surface finish

- Applicable to a wide range of materials

- Suitable for both dry and wet blasting

- Efficient and long-lasting, with high recycling capabilities

- Consistent surface treatment results due to high roundness and low abnormal sphere formation

- Eco-friendly and safe for human health

- Minimal equipment loss due to ceramic shot's features

Technical Parameters:

| Ceramic Bead Blasting | Ceramic Cleaning Media |

|---|---|

| Ceramic bead blasting media | Ceramic beads blasting media |

| Zro2 | 65% |

| Size | 850-1180μm |

| Color | White |

| Usage | Sandblasting, Deburring |

| Material | Ceramic |

| Application | Abrasive Refractory Industry |

| Shape | Customizable |

| Name | Ceramic Cleaning Media |

| Process | Bead Blasting |

Applications:

- Sandblasting is more efficient, thorough, and cost-effective compared to other pretreatment techniques.

- The sandblasting process allows for flexibility in selecting the level of cleanliness and roughness needed for the workpiece.

- Medical field: for surface treatment of stainless steel surgical instruments and titanium alloy human implants by removing burrs.

- High iron field: for sandblasting surface of high iron aluminum alloy parts to improve the metal texture and create a smooth satin effect. Also used for grinding and finishing high-speed rails.

- Automotive industry: ceramic beads can be used for surface cleaning and deburring of automotive engine castings. They are also used to clean welds and welding spots on the car floor before spraying. Used in shot peening of automobile springs to improve fatigue life. Additionally, they can be used for beautification and sandblasting of aluminum alloy automobile wheels to reduce stress and improve impact resistance.

- Molds and machining: used for sandblasting stainless steel, copper, and aluminum alloy molds, such as tire molds, injection molds, and stamping molds, to improve surface finish. They are also effective in removing flash and burrs from machined parts.

- Electronic equipment industry: ceramic beads are used for sandblasting aluminum alloy or stainless steel shells of mobile phones, tablets, and watches. They can control the surface roughness and gloss according to the requirements and have fingerprint-resistant properties.

- Kitchenware industry: for sandblasting high-quality stainless steel cookware, pot bottoms, soup spoons, and other products to achieve a delicate metal texture and some antibacterial ability.

- Glass products industry: used for atomization treatment of glass, replacing the chemical etching process with hydrofluoric acid to prevent pollution.

- Shot peening of aviation parts: for improving the fatigue resistance of carbon steel, titanium alloy, aluminum alloy, and other aircraft mechanical parts and eliminating surface stress. Used in surface strengthening of aircraft wings, aero engine turbine blades, turbine discs, gears, and landing gear.

Customization:

Model Number: B10

Place of Origin: Changsha China

Minimum Order Quantity: 500kg

Price: Negotiation

Packaging Details: 25kg/barral, 25kg/bag, 1t/pallet

Delivery Time: 5-15 work days

Payment Terms: L/C, T/T

Supply Ability: 2000t per year

Ceramic Bead Blasting is a type of blasting media made from zirblast ceramic beads, which are highly durable and impact-resistant. These beads are perfect for deburring and surface finishing of various materials.

At Fine-Tech, we offer customized services for our Ceramic Bead Blasting product. We understand that every customer has unique needs and requirements, and we strive to meet them. Our customized services include:

- Size customization: We can adjust the size of the ceramic beads according to your specific needs.

- Shape customization: We can provide ceramic beads in different shapes, such as spherical, angular, and irregular, to suit your blasting requirements.

- Packaging customization: We can pack the ceramic beads in different packaging options, such as barrels, bags, or pallets, as per your preference.

- Delivery customization: We offer flexible delivery options to ensure your order reaches you on time.

- Material customization: We can provide ceramic beads made from different materials, such as zirconia silicate, zirconia alumina, or alumina, depending on your application needs.

Packing and Shipping:

Packaging and Shipping

Our Ceramic Bead Blasting product is carefully packaged to ensure safe and secure delivery to our customers. Each package includes the following:

- Individual containers of Ceramic Bead Blasting

- Product label with product name and information

- Material safety data sheet (MSDS)

- Package tracking information

We offer a variety of packaging options to meet your specific needs, including:

- Plastic jars, buckets, or bags for small to medium orders

- Cardboard boxes or drums for larger orders

- Custom packaging available upon request

Our shipping methods are also flexible and can be tailored to your preferences. We offer:

- Standard ground shipping via UPS, FedEx, or USPS

- Expedited shipping options for urgent orders

- International shipping services

Our team takes great care in packaging and shipping our Ceramic Bead Blasting product to ensure it arrives in perfect condition. For any questions or special requests, please contact our customer service team for assistance.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is Fine-Tech. - Q: What is the model number of this product?

A: The model number of this product is B10. - Q: Where is this product manufactured?

A: This product is manufactured in Changsha, China. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 500kg. - Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable. - Q: What are the packaging details for this product?

A: This product is packaged in 25kg barrels, 25kg bags, and 1 ton pallets. - Q: How long is the delivery time for this product?

A: The delivery time for this product is 5-15 work days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are L/C and T/T. - Q: What is the supply ability for this product?

A: The supply ability for this product is 2000 tons per year.