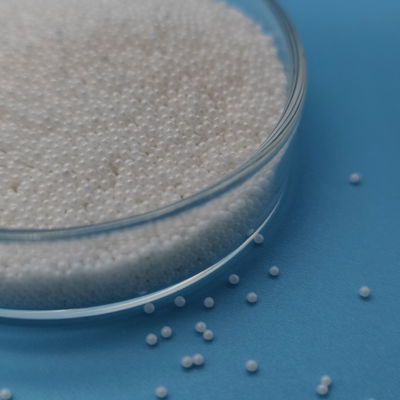

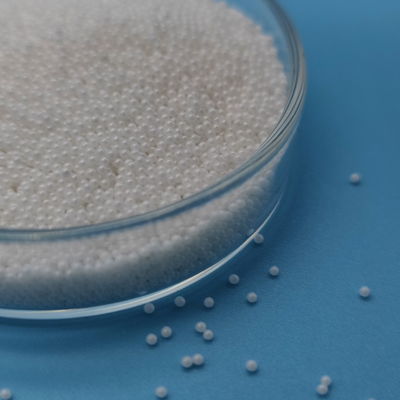

High Abrasive Strength Ceramic Blasting Abrasive Reliable Performance

| Heat Resistance | High | Dust Production | Low |

|---|---|---|---|

| Durability | High | Chemical Resistance | High |

| Hardness | High | Reusability | Low |

| Highlight | Chemical Resistant Ceramic Blasting Abrasive,Heat Resistant Abrasive Blasting Media |

||

Product Description:

It has the features of low dust content, high degree of sphericity, smooth spherical and high toughness to ensure the excellent performance. Not only can they be used for cleaning up all kinds of molds,turbomachinery parts, engine parts but also can be used for removing various rusts, scales, oxide layers, paint residues, coatings and burrs on aircraft components,aluminium and other non-ferrousmetal alloys.

Additionally, Ceramic Beads with superior surface brightness can make the treated parts have an excellent appearance for a variety of applications such as aerospace, automotive, sports goods,etc. It can bring out excellent surface finish,which makes the treated parts not only have beautiful appearance, but also fits certain technical specifications.

.

Applications:

Ceramic bead sandblasting produces a uniform and uneven rough surface on the cleaned surface, which is beneficial for the mechanical bonding of coatings to the substrate. Through the use of clean compressed air to blow ceramic sand onto the workpiece, compressive stress is applied to its surface, removing any oxide film and causing a lattice distortion of the metal. This roughens the surface and creates a highly reactive coating, making it an important preprocessing method.

The quality of surface preprocessing with sandblasting affects the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If the process is not done properly, rust may start to form underneath the coating. Potentially causing it to chip and flake away.

Ceramic bead sandblasting is used for various applications in different industries:

For instance, in the electronics industry, ceramic shot blasting is used to sandblast shells of mobile phones, tablets, and watch casings made of either aluminum alloy or stainless steel. This can adjust the roughness and gloss of the surface to help create an anti-fingerprint effect.

In the kitchenware industry, ceramic shot blasting is used to sandblast high grade stainless steel pot bottoms, spoons, and other cookware items, offering them a delicate metallic texture and certain antibacterial properties.

In the glass products industry, ceramic shot blasting is used to form glass products instead of hydrofluoric acid chemical etching, helping to prevent water pollution.

Furthermore, ceramic bead sandblasting is also used to improve fatigue resistance and eliminate surface stress in aircraft parts made out of carbon steel, titanium alloy, or aluminum alloy. This includes strengthening of wings, turbine blades, turbine discs, gears, and landing gears.

Customization:

Customize your Ceramic Blasting Abrasive with Fine-tech! Our product, model B20, is certified by ISO9001 and has a minimum order quantity of 500KG. We offer competitive prices and various packaging options such as 25kg/barrel, 25kg/bag, and 1t/pallet, with delivery time of 5-15 work days. Payment terms include L/C and T/T. Our supply ability is 2000t per year. Our Ceramic Blasting Abrasive is made of Ceramic and has a high chemical resistance and hardness. It is white in color and available in grit shape. Our media blasting booths, sandblasting booths equipment, and floor model abrasive blasting cabinet are perfect for your blasting needs.

Support and Services:

Our technical support and service team are always available to help with any questions you may have about our Ceramic Blasting Abrasive. We provide expert advice in selecting the best abrasive for the job, and our team can help troubleshoot any problems you may experience. We offer on-site maintenance and repair services, as well as online technical support. Our knowledgeable technicians are available to answer your questions and provide guidance on the use and maintenance of our Ceramic Blasting Abrasive. We also offer custom-made abrasive solutions to meet your specific needs.