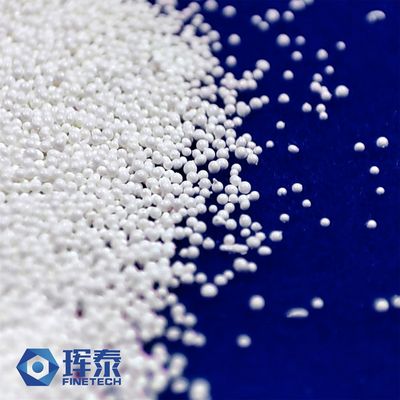

Versatile White Ceramic Blasting Media with Alumina Oxide Abrasive Grain

| Melting Point | 2050°C | Specific Gravity | 2.6-2.8 |

|---|---|---|---|

| Hardness | 7.5-8.5 | Maximum Operating Temperature | 1700°F |

| Material | Ceramic | ||

| Highlight | Versatile White Ceramic Blasting Media,7.5 Hardness Ceramic Blasting Media,Alumina Oxide Ceramic Media |

||

Product Description:

Features:

- Product Name: Ceramic Blasting Media

- Hardness: 7.5-8.5

- Refractoriness: 1790°C

- Maximum Operating Temperature: 1700°F

- Specific Gravity: 2.6-2.8

- Chemical Composition: Al2O3

- Ideal for industrial ceramic parts

Technical Parameters:

| Property | Value |

|---|---|

| Refractoriness | 1790°C |

| Maximum Operating Temperature | 1700°F |

| Chemical Composition | Al2O3 |

| Specific Gravity | 2.6-2.8 |

| Hardness | 7.5-8.5 |

| Material | Ceramic |

| Melting Point | 2050°C |

| Shape | Irregular |

| Color | White |

| Abrasive Grain | Alumina Oxide |

| Application | industrial ceramic components, silicon carbide ceramic parts, industrial ceramic components |

Applications:

1. Medical treatment: surface treatment such as deburring of stainless steel surgical instruments and titanium alloy human implanted devices.

2. High iron field: it can be used for sandblasting the surface of high iron aluminum alloy parts to improve the metal texture and form a smooth satin effect. Used for grinding and finishing of high-speed rail.

3. Automotive field: ceramic shot can be used for surface cleaning and deburring of Automotive Engine Castings; It is used to clean the welds and welding spots on the car floor and prepare for subsequent spraying; Used for shot peening of automobile springs to improve fatigue life. It is used for beautification and sandblasting of aluminum alloy automobile wheels to eliminate stress and improve impact resistance.

4. Mold and machining: used for sand blasting of stainless steel mold, copper mold and aluminum alloy mold, such as tire mold, injection mold and stamping mold, to improve surface finish. Clean the flash and burr of machined parts.

Support and Services:

Ceramic Blasting Media offers comprehensive technical support and service to ensure our customers can get the most out of our products. Our team of experts is available to answer any questions you may have about our products and provide assistance with setup, troubleshooting, and maintenance.

For technical support, we offer a range of options, including phone and email support, as well as online documentation and tutorials. Our experienced technicians can provide personalized assistance via remote control or on-site visits.

Our service team is available to help you with installation, repairs, and upgrades, and provide support for product warranties. We also offer maintenance plans to keep your equipment in top condition.

If you have any questions or need technical support or service, please contact us at Ceramic Blasting Media.