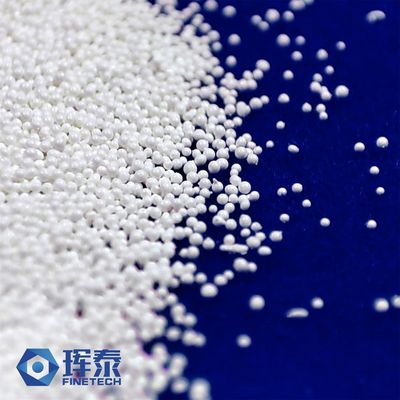

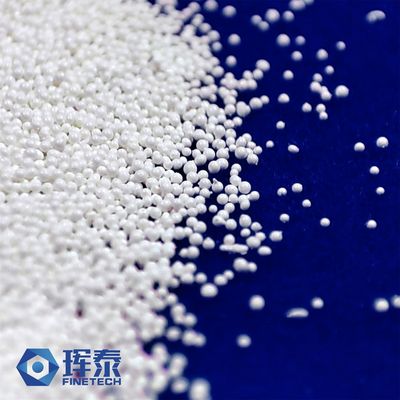

Revolutionize Your Blasting Process with Ceramic Blasting Media Refractoriness 1790°C

| Specific Gravity | 2.6-2.8 | Hardness | 7.5-8.5 |

|---|---|---|---|

| Maximum Operating Temperature | 1700°F | Melting Point | 2050°C |

| Material | Ceramic | Shape | Irregular |

| Highlight | Refractoriness Ceramic Blasting Media,1790°C Ceramic Blasting Media,Revolutionize Ceramic Blasting Media |

||

Product Description:

They are suitable for sandblasting the surfaces of various steel, aluminum and other non-ferrous metal alloys to remove oxides, rust, sand, coatings and burrs. It can clean molds, engine parts, turbomachinery parts, welded steel parts, forged and cast metals and other various industrial components. Providing high quality components with outstanding aesthetic appearance in a variety of applications such as automotive, aerospace, electronics, home appliances, sporting goods and construction to achieve outstanding smooth and even surface finish on the parts being treated.

Features:

- Product Name: Ceramic Blasting Media

- Shape: Irregular

- Specific Gravity: 2.6-2.8

- Color: White

- Maximum Operating Temperature: 1700°F

- Material: Ceramic

- Additional Properties: Silicon Carbide Ceramic Parts, Industrial Ceramic Parts, Ceramic Bead Blasting

Applications:

Blasting cleaning: to remove burrs, casting slag and other defects and dirt on the surface of the workpiece and also residues of the molds;

Blasting finish: to show natural metal color and achieve uniform surface matting effect.

Pretreatment: to get clean surface and frosted rough surface before Anodizing and coating.

Shot peening for metal parts in aerospace industry to improve the surface strength, eliminate the stress, reducethe mental weights;

Shot peening in automotive industry such as gearbox gears, automotive aluminum hubs etc. to extend the anti-fatigue life bystress relieving, peen-forming and peen-straightening.

Shot peening in nuclear and chemical equipment.

Shot peening in medical industry.

Customization:

- Ideal for industrial ceramic parts and components

- High-performance with a high specific gravity

- Irregular shape for an even, smooth surface

- Alumina oxide for superior durability and cutting power

- High refractoriness up to 1790°C

- White color for visible particles

Support and Services:

At [Company Name], we provide technical support and service for our Ceramic Blasting Media products. Our technical support team is available to answer any questions you may have about our products and help you determine which product is best suited for your particular application.

We are committed to ensuring the highest level of customer satisfaction and providing you with quality products and services. We offer a variety of support services, including:

- Onsite support and training

- Remote technical support

- An online knowledge base with product documentation, troubleshooting tips, and more

- Product demonstrations and presentations

- Direct access to our engineering team

For any questions or support needs, please don’t hesitate to reach out to our technical support team. We’re here to help you get the most out of your Ceramic Blasting Media products.