Zirconium Silicate Ball With Abrasion Resistance Excellent 425-600μM

| Refractive Index | 1.54-1.57 | Melting Point | 2,370 °C |

|---|---|---|---|

| Color | White | Material | Zirconium Silicate |

| Shape | Ball | Heat Resistance | Excellent |

| Density | 3.6-3.9 G/cm3 | Abrasion Resistance | Excellent |

| Highlight | Abrasion Resistant Zirconium Silicate Ball,600 uM Zirconium Silicate Ball,White Zircon Silicate Spheres |

||

Product Description:

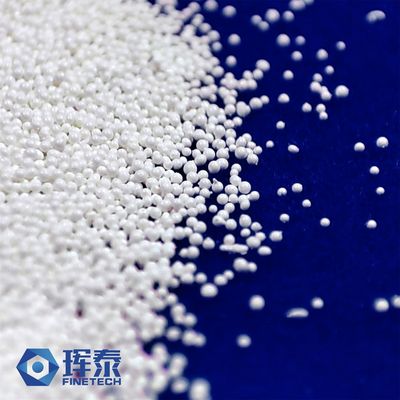

Zirconium Silicate Ball With Abrasion Resistance Excellent 425-600μM

Ceramic Beads blasting media is the result of modern technology. The high-tech blasting media are made using high quality zirconia powder as the primary material. This powder is then fused in an electric furnace with a temperature of at least 2000 degrees. Through a special technology, the powder is crafted into different micro beads.

The advantages of this technology are impressive. Ceramic Beads blasting media is highly durable and resists heat. It is also chemically stable, meaning it doesn’t change properties when in contact with different chemicals. Furthermore, its size and shape can easily be adjusted.

Ceramic Beads blasting media is used in various applications. It can be used to grind materials and create a smooth surface. It is also used to clean surfaces, sharpen edges, polish or degrease.

Features:

This product has a strong chemical resistance, guaranteeing a consistent surface blasting effect. It also has a low dust emission, meaning that the work piece surface is kept clean and no hidden danger of silicosis or any harm to human body.

Furthermore, it is not easy to break, as it is recyclable – allowing for fewer refueling times and a higher working efficiency.

Technical Parameters:

| Attribute | Value |

|---|---|

| Melting Point | 2,370 °C |

| Color | White |

| Refractive Index | 1.54-1.57 |

| Density | 3.6-3.9 G/cm3 |

| Heat Resistance | Excellent |

| Hardness | 7.5-8 Mohs |

| Abrasion Resistance | Excellent |

| Shape | Ball |

| Material | Zirconium Silicate |

| Product Name | Zirconium Silicate Ball, Zircon Silicate Spheres, Silicate Zircon Beads |

Applications:

Ceramic bead sandblasting is an essential pre-treatment method that is used to improve the physical bonding of the coating to the substrate metal. Compressed air is used to propel clean ceramic sand particles at high speeds onto the surface of the workpiece, generating compressive force which grants numerous advantages. It removes any surface oxide films, causes lattice distortion in the metal and most importantly, creates a smooth, rough and highly reactive surface for the coating to bond to.

The efficacy of this pretreatment process is able to dictate the adhesion, appearance, moisture resistance and corrosion resistance of the coating. If pre-treatment is not completed effectively, rust will start to spread beneath the coating, resulting in the coating flaking off.

Customization:

We provide Zirconium Silicate Ball with the brand name of Fine-tech, Model Number z210. This product is certified with ISO9001 and the minimum order quantity is 500KG. The price is negotiable and the packaging detail is 25kg/barrel, 25kg/bag, 1t/pallet. The delivery time is 5-15 work days, and the payment terms are L/C, T/T. The supply ability is 2000t per year. The material is Zirconium Silicate, and the refractive index is 1.54-1.57. The hardness is 7.5-8 Mohs and it has excellent heat resistance and abrasion resistance. We are based in Changshan China.

Support and Services:

We provide comprehensive technical support and service for Zirconium Silicate Ball. Our experienced professionals provide you with the following services:

- Product selection and application guidance

- Product installation and maintenance

- Troubleshooting and repair

- Technical training and seminars

- Customized solutions for specific customer needs

We are committed to providing you with the highest quality service and products to meet your needs. Contact us today for more information about our services and products.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is Fine-tech.

- Q: What is the model number of this product?

- A: The model number of this product is z425.

- Q: Where is this product made?

- A: This product is made in Changshan China.

- Q: What is the minimum order quantity?

- A: The minimum order quantity is 500KG.

- Q: What is the pricing of this product?

- A: The pricing of this product is negotiable.