-

Ceramische het Vernietigen Media

-

Het ceramische Parel Vernietigen

-

Ceramisch het Vernietigen Schuurmiddel

-

De Bal van het zirconiumsilicaat

-

Zirconiumdioxyde Malende Media

-

Wit Aluminiumoxyde

-

Garnet Abrasive Sand

-

Het ceramische Geschotene Uithameren

-

Bruin Aluminiumoxyde

-

Het Carbide van het carborundumsilicium

Achieve Perfect Surface Preparation with Ceramic Blasting Media Delivered by Sea Way Delivery

Contacteer me voor vrije steekproeven en coupons.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Als u om het even welke zorg hebt, verstrekken wij de online-Help van 24 uur.

x| Usage | Surface Preparation | Delivery Way | Sea Way,Air Way,land Way,Railway |

|---|---|---|---|

| Processing Method | Melting | Type | Ceramic Blasting Media |

| Commodity | Ceramic Blasting Media | Chemical Index | 60-66% ZrO2, 25-30% SiO2, 7-13%Al2O3 |

| Ture Density | 3.86cm³ | Abrasive Grain | Alumina Oxide |

| Markeren | ceramic blasting media for surface preparation,ceramic blasting media with sea delivery,ceramic blasting media for industrial use |

||

Product Description:

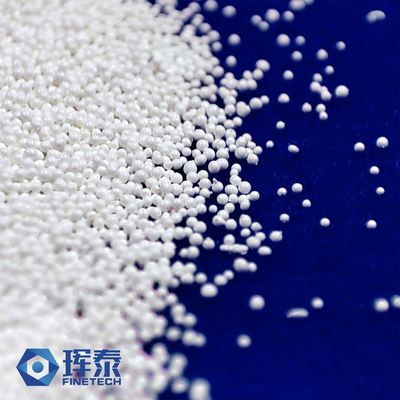

Ceramic Blasting Media Micro Beads are a high-quality abrasive material designed for various industrial applications, particularly in the field of ceramic bead blasting. Known for their exceptional performance and durability, these micro beads are composed of Alumina Oxide, making them an ideal choice for precision blasting operations.

As a specialized Ceramic Blasting Media, these micro beads are specifically formulated to provide efficient and effective surface treatment for a wide range of materials. Whether you are working on industrial ceramic parts or components, these beads offer consistent and reliable results, ensuring a smooth finish and enhanced durability.

Our Ceramic Blasting Media Micro Beads are meticulously engineered to meet the highest standards of quality and performance. With a chemical index of 60-66% ZrO2, 25-30% SiO2, and 7-13% Al2O3, these beads deliver superior abrasive properties that are essential for achieving precise and uniform surface treatment.

Designed for versatility, these Ceramic Blasting Media Micro Beads can be delivered through multiple channels, including Sea Way, Air Way, Land Way, and Railway. This flexibility ensures that you can receive your supply of micro beads promptly and efficiently, no matter your location or logistical requirements.

When it comes to ceramic bead blasting, having the right abrasive material is crucial for achieving optimal results. Our Ceramic Blasting Media Micro Beads offer exceptional hardness and toughness, making them suitable for a wide range of blasting applications. Whether you are working on intricate industrial ceramic parts or robust industrial ceramic components, these micro beads provide the abrasive power needed to achieve a superior finish.

With their precise composition and consistent quality, our Ceramic Blasting Media Micro Beads are trusted by professionals in various industries for their reliability and performance. Whether you are looking to remove surface contaminants, deburr edges, or create a uniform finish, these micro beads are the ideal choice for achieving outstanding results.

Invest in the quality and precision of Ceramic Blasting Media Micro Beads for your blasting operations, and experience the difference that superior abrasive materials can make. Enhance the efficiency and effectiveness of your surface treatment processes with these high-performance micro beads, trusted by professionals for their exceptional quality and reliability.

Features:

- Product Name: Ceramic Blasting Media

- Chemical Index: 60-66% ZrO2, 25-30% SiO2, 7-13%Al2O3

- Ture Density: 3.86cm³

- Commodity Name: Ceramic Blasting Media Micro Beads

- Commodity: Ceramic Blasting Media

- Usage: Surface Preparation

Technical Parameters:

| Processing Method | Melting |

| Color | White |

| Chemical Index | 60-66% ZrO2, 25-30% SiO2, 7-13% Al2O3 |

| Commodity Name | Ceramic Blasting Media Micro Beads |

| Grain Size | 0.8-20mm |

| Delivery Way | Sea Way, Air Way, Land Way, Railway |

| Abrasive Grain | Alumina Oxide |

| Commodity | Ceramic Blasting Media |

| Specificaton | B120 |

| Specific Gravity | 2.6-2.8 |

Applications:

Ceramic Blasting Media, such as the Fine-tech Z210 model, is a versatile and effective option for a wide range of surface preparation tasks in various industries. With its composition of 60-66% ZrO2, 25-30% SiO2, and 7-13% Al2O3, this product offers superior performance in removing contaminants, rust, scale, and old coatings from surfaces.

The Product Application Occasions and Scenarios for the Ceramic Blasting Media (Z210) by Fine-tech are numerous. This product is ideal for use in industries such as aerospace, automotive, marine, and metal fabrication. Its high density of 3.85 G/cm3 ensures efficient and consistent blasting results, making it suitable for both delicate and robust surfaces.

One of the key application scenarios for Ceramic Bead Blasting media is in the preparation of industrial ceramic components. Whether it's cleaning molds, deburring ceramic parts, or achieving a specific surface finish, the Z210 model delivers precise and uniform results. Its certification of ISO9001 guarantees quality and reliability in every batch.

With a minimum order quantity of 500KG, customers have the flexibility to order as per their requirements, while the Packaging Details of 25kg/barrel, 25kg/bag, or 1t/pallet ensure convenient handling and storage. The negotiated price and flexible Payment Terms of L/C or T/T make purchasing the Ceramic Blasting Media cost-effective and hassle-free.

Furthermore, the Supply Ability of 2000t Per Year ensures a steady and reliable source of this high-quality blasting media. The quick Delivery Time of 5-15 work days enables businesses to maintain their operations without delays.

In conclusion, Fine-tech's Ceramic Blasting Media (Z210) is a top choice for industrial surface preparation needs, offering efficiency, quality, and versatility. Whether it's preparing industrial ceramic components or achieving a specific surface finish, this product delivers consistent and exceptional results.